Enhancing Connectivity: A Closer Look at Optical Fiber Splicing!

Enhancing Connectivity: A Closer Look at Optical Fiber Splicing!

In the world of high-speed data transmission, optical fiber plays a vital role in delivering lightning-fast and reliable connectivity. But have you ever wondered how those tiny strands of glass are seamlessly joined together? Let’s dive into the fascinating world of optical fiber splicing!

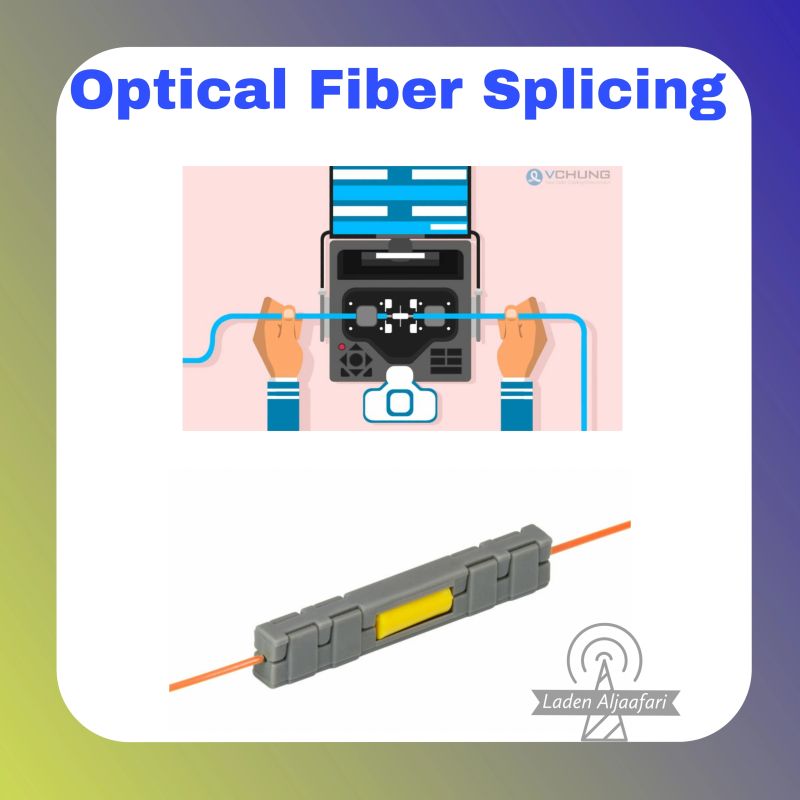

Optical fiber splicing is the process of connecting two fiber optic cables to ensure a continuous and low-loss connection for transmitting light signals. With applications spanning telecommunications, data centers, and more, the success of splicing directly impacts our digital lives.

Here’s a glimpse into the splicing process:

1️⃣ Preparation: The fiber optic cables undergo meticulous cleaning and coating removal to create a clean surface for splicing.

2️⃣ Cleaving: Precise cleaving of the fibers is crucial for a seamless connection. This step involves scoring and breaking the fibers to achieve a clean and flat end face.

3️⃣ Splicing process:

It involves two types Splicing /

** Fusion Splicing**: The most prevalent technique, fusion splicing, involves aligning the prepared fibers and fusing them together using an electric arc. This results in a solid and permanent connection.

** Mechanical Splicing**: Another method is mechanical splicing, which relies on a precision alignment mechanism and a mechanical splice to join the fibers. Gel or index-matching fluid helps reduce loss at the splice point.

4️⃣Splice Protection: To ensure long-term reliability, the splice point is protected using sleeves or heat shrink tubes, providing physical protection and maintaining fiber alignment.

5️⃣ Testing and Verification: Finally, the spliced fiber is tested using optical time-domain reflectometers (OTDRs) or other testing equipment to measure loss and reflectance at the splice point.

The process of optical fiber splicing typically includes fiber preparation, cleaving, alignment, fusion or mechanical splicing, splice protection, and splice testing. It requires specialized training, knowledge, and equipment to ensure accurate and reliable splices. ️

Disclaimer – This post has only been shared for an educational and knowledge-sharing purpose related to Technologies. Information was obtained from the source above source. All rights and credits are reserved for the respective owner(s).

Keep learning and keep growing

Source: LinkedIn

Credits: Mr. Laden Aljaafari